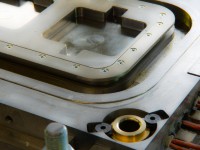

SMC (Sheet Molding Compound) / BMC (Bulk Molding Compound) is one of our most efficient processes. Material of which main components are resin, glass reinforcement and fillers, in the form of sheets (SMC) or bulk (BMC), is placed in a hot mold and pressed under high pressure, causing it to be spread inside the mold. For this purpose presses with a pressure of up to 700 tons and bench up to 2x1,3 m are used. In the course of a few minute process a full polymerization is ensured.

The life span of molds is even several hundred thousand of pieces. We have also developed a system of low-cost molds for the production of small series, limited to several hundred pieces. The main advantages of the technology are high repeatability, quality and performance precision of parts.

We manufacture mostly external and internal components for vehicles. Materials we use for bus parts are in compliance with Directive 95/28/EC and ECE Reg. 118. For railway parts, materials are EN 45545 HL3 certified. Components for the energy industry are made of a material with high dielectric properties.