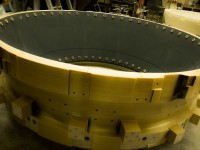

Filament Winding / Wet Winding is a manufacturing method we use mainly for the production of cylindrical elements of power generators. This technology involves wrapping strained filaments onto a rotating spindle while soaking them in resin. After a cylinder has been formed, it is placed in the heating chamber to cure the resin.

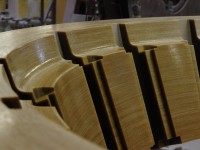

With this method we produce elements with an external diameter of up to 3,5 m, a ring thickness of 0,75 m and a crude weight of over 4000 kg. The next stage of production is the machining of parts on a CNC lathe and their milling at CNC machining centers.